Tirolpi

CNC

We provide injection moulds, blanking dies and machining services. We have our own construction department and a specialized machinery park enabling the production of all types of production details. We provide CNC services such as:

milling

machining

CNC turning

HIGH LEVEL CNC SERVICES

CNC services are our specialty – we offer professional machining, using modern, most precise machines. Our offer is very diverse – we provide various types of metal processing, turning, milling, drilling, and other CNC services tailored to the needs of our Clients.

MACHINING – WHAT IS IT?

Machining is a specialized technology used to give the processed workpiece the expected shape by separating the excess material with special CNC machines. Numerically controlled machine tools allow for a very accurate reconstruction of the design of a given element. The process is repeatable and enables fast production of many parts from a variety of materials. This is why CNC service is the most popular method used to produce metal parts and more.

We have modern processing devices that allow for precise production of components, even of very complex shapes. We perform CNC milling using various materials, incl. plastics, steel, non-ferrous metals.

We make the highest quality injection moulds suitable to your product.

OUR SERVICES INCLUDE:

CNC milling – cutting method performed with milling machine, enabling the processing of shaped surfaces, different planes or grooves; during this process, the milling machine performs rotary motion, while the material performs feed motion towards the CNC machine tool. CNC turning – machining aimed at removing excess material, during which the processed material (workpiece) is rotated, while the tool remains stationary. Drilling – enables cutting holes in the material.

Threading – enables adding external or internal threads.

All CNC services are tailored to the needs of our Clients.

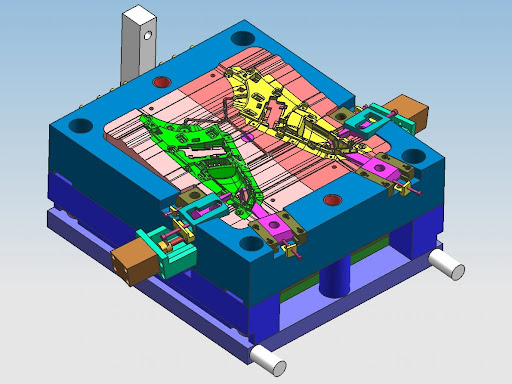

Injection moulds

The injection mould consists of many components that enable low-volume and large-volume production of plastic products.

The mould has the following functional systems:

cavities or moulding cavity

gating system

mould cooling system

moulding ejection system

ingot removal system

guiding and retaining elements for the mould halves

plate and segment drives

housing

There are different types of injection moulds. Depending on the gating system solution, there are cold runner and hot runner moulds.

According to the number of moulding cavities, there are single-cavity and multi-cavity moulds, as well as moulds with one parting and two parting planes.

Each of the given types of moulds has its own characteristic structure that enables low or large-volume production, production of profiles of normal or increased quality and accuracy, or production of moulded parts with a simple or complex structure.

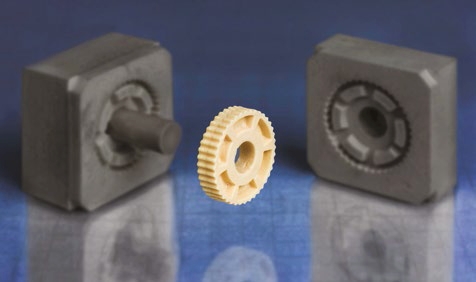

Mould production can be divided into several stages.

1. Detail design

The first stage is the preparation of the detail design in 2D and 3D, depending on whether the detail has a simple or complex shape.

2. Mould design

A detailed design of the injection mould is based on the detail design and detailed arrangements with the Client regarding the mould type (hot runner, cold runner, single-cavity, multi-cavity).

3. Making the mould, preliminary tests, refining the mould after preliminary tests, final tests at the Client's place.

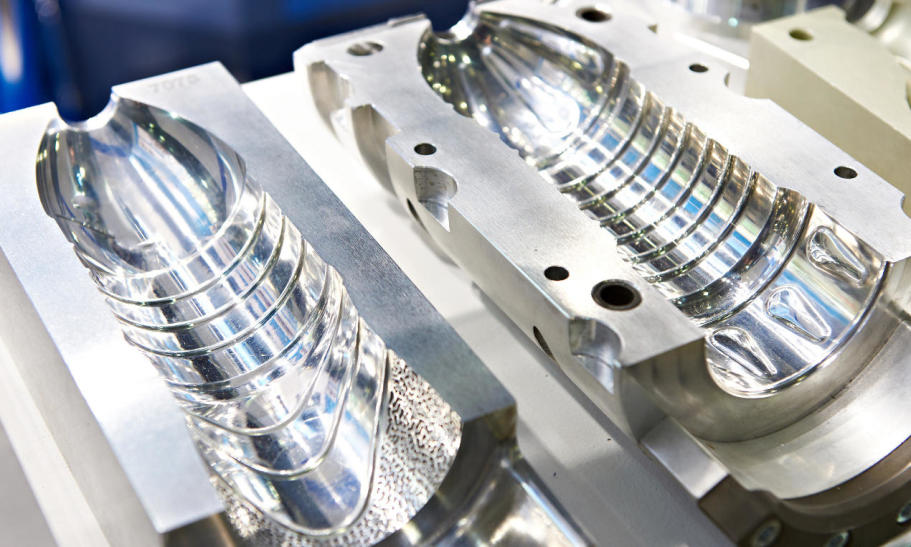

We also specialize in the production of injection mould cavities on the Client's request, which must be quickly and precisely milled and polished or hollowed to obtain the appropriate texture of the cavity surface. We also make non-standard injection mould components.

Are you looking for an injection mould cavity contractor to assemble your own injection mould? or the cavity is damaged and you need to make a new one? We can provide these services. If you are looking for – CNC Services in Kielce, CNC Services in Radom or CNC Services in Starachowice and Szydłowiec, you have come to the right place.

.jpg)